ENCOS OPTICAL GAS IMAGING

Optical Gas Imaging (OGI) cameras enable thermographers to visualize hydrocarbons based on their unique electromagnetic radiation absorption characteristics. Most hydrocarbons absorb energy in the mid-wave (3 – 5 micrometer) infrared band along the electromagnetic spectrum. Specialized and properly tuned spectral filters only allow these wavelengths to pass through. Therefore, hydrocarbon gases appear as black (absence of radiant energy) plumes of smoke when viewed through an OGI camera. This technology has piqued the interest of the United States Environmental Protection Agency (USEPA).

Optical Gas Imaging (OGI) cameras enable thermographers to visualize hydrocarbons based on their unique electromagnetic radiation absorption characteristics. Most hydrocarbons absorb energy in the mid-wave (3 – 5 micrometer) infrared band along the electromagnetic spectrum. Specialized and properly tuned spectral filters only allow these wavelengths to pass through. Therefore, hydrocarbon gases appear as black (absence of radiant energy) plumes of smoke when viewed through an OGI camera. This technology has piqued the interest of the United States Environmental Protection Agency (USEPA).

Numerous EPA air pollution standards require specific work practices for equipment leak detection and repair (LDAR). The current work practice requires the use of a monitor which meets required performance specifications. This work practice is based on 25-year-old technology. New technology has been developed which we believe provides equal, or better, environmental protection than that provided by the current work practice. This action proposes a voluntary alternative work practice (AWP) for finding leaking equipment using optical gas imaging.

Federal Register / Vol. 71, No. 66 / Thursday, April 6, 2006 / Proposed Rules

Due to the greater accessibility and continued advancement of OGI technology, the ability to replace Method 21 and supplement Fugitive Emissions and Greenhouse Gas (GHG) monitoring represents a prevailing trend within the compliance industry. EPA regards OGI as the Best System for Emissions Reduction (BSER) and has been made an option for LDAR, GHG, and Fugitive Emission Monitoring compliance for recent NSPS regulations. In 2011, the EPA recognized that OGI technology offered significant advantages to Method 21 and revised their written regulations to include it as an alternative work practice (AWP)*. Now, with the introduction of NSPS OOOOa, OGI inspections are shifting to a primary work practice.

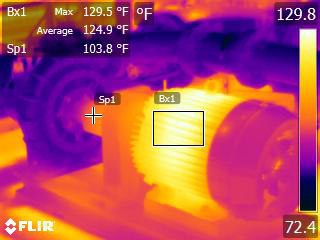

Whether to avoid manufacturing downtown and production losses or mitigating potential fire and safety hazards, IR technology is in a class of its own. Infrared thermography is the process of acquisition and analysis of thermal information from non-contact thermal imaging devices. This thermal information can aid in the detection of electrical anomalies, poor equipment performance, and other heat related issues without interrupting services. Condition based monitoring and thermal performance often coincide in mitigating potential process upsets and safety hazards. Infrared Thermography is a proven non-invasive and non-destructive test method that safely and accurately locates problems, prior to failure while simultaneously contributing to comprehensive quality control and process monitoring programs.